Disclosure

This website is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for us to earn fees by linking to Amazon.com and affiliated sites.

Choosing the best inline skate wheels isn’t a one-size-fits-all answer—it depends on your skating style, surface, and goals. Did you know that wheel hardness can affect your speed by up to 20%? Whether you’re a beginner gliding through the park or an aggressive skater grinding rails, the wrong wheels can turn your session into a struggle. Many skaters assume harder wheels are always better, but that’s a myth—soft wheels offer critical grip for tricks and rough terrain. In this guide, you’ll unlock the science behind wheel selection, avoid costly mistakes, and find the perfect match for your needs.

Best Inline Skate Wheels for Different Skating Styles

Hyper Concrete Plus Wheels (84A, 80mm)

Perfect for urban skating and rough surfaces, the Hyper Concrete Plus Wheels (88A hardness, 80mm diameter) offer superior shock absorption and durability. Their high-rebound urethane ensures a smooth ride while maintaining speed, making them ideal for commuters and street skaters who need grip and resilience.

- N1 inline skates wheels in the world. Most durable one (long life use)….

- PACK: 8 WHEELS (you receive 2 * 4 wheels pack). No bearings included….

- USE: All rough and smooth outdoor surfaces(good for indoor as well, nice…

Labeda Asphalt 85A Wheels (76mm)

Designed for outdoor speed and agility, the Labeda Asphalt 85A Wheels (76mm) provide an excellent balance of hardness and grip. Their slightly softer 85A durometer prevents slipping on uneven terrain, while the optimized core reduces weight for faster acceleration—great for fitness skaters and marathoners.

- Includes 8 76mm Wheels, 16 Hybid Ceramic Bearings, 8 8mm Spacers, and 8 6mm…

- This wheel was made for those outdoor hockey players that get tired of…

- Amp Hybrid Ceramic bearings are like stimulants for your wheels. With this…

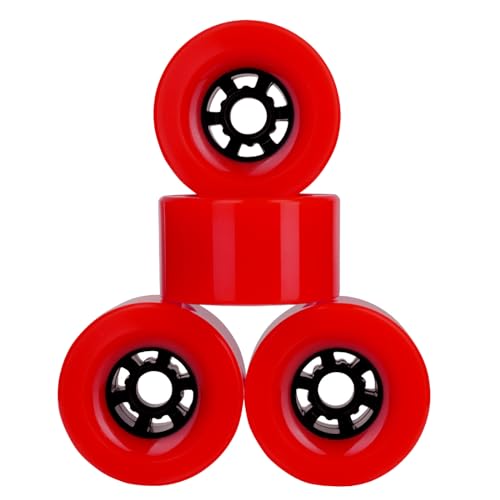

Cruiser Blank Wheels (58mm, 90A)

Aggressive skaters swear by the Cruiser Blank Wheels (58mm, 90A) for park and ramp skating. The 90A hardness ensures slide control during grinds, while the compact size enhances maneuverability. The high-quality urethane resists flat spots, making them a long-lasting choice for trick-focused skaters.

- 90x52mm PU wheels

- 78A durometer

- 44.45mm center-set hub

Understanding Wheel Hardness: The Durometer Scale Explained

Wheel hardness, measured on the durometer scale (A-scale), is the most critical factor affecting your skating performance. Ranging from 74A (softest) to 100A (hardest), this rating determines grip, shock absorption, and durability. Many beginners mistakenly choose wheels based solely on size, but hardness directly impacts control and fatigue—especially on rough surfaces.

How Hardness Affects Performance

Softer wheels (74A-85A) deform slightly on contact, creating more surface area for grip. This makes them ideal for:

- Outdoor skating (e.g., Labeda Asphalt 85A): Absorbs vibrations from cracks and pebbles

- Beginner skaters: Prevents slips during turns and stops

- Dance/artistic skating: Allows precise edge control

Conversely, harder wheels (86A-100A) maintain shape under pressure, reducing friction for faster speeds. The Hyper Concrete Plus (88A) exemplifies this hybrid approach—firm enough for urban skating yet soft enough to handle sidewalk seams.

The Trade-Off: Speed vs. Control

A common misconception is that harder wheels always equal better performance. While a 90A wheel might excel in a skate park (like the Undercover Team Blank), that same hardness would be dangerously slippery on wet pavement. The key considerations:

- Surface texture: Rough asphalt demands softer wheels (≤85A), while smooth rinks allow harder setups (≥88A)

- Skater weight: Heavier riders (>180 lbs) compress softer wheels excessively, requiring adjustments (+5A durometer)

- Discipline: Slalom skaters use dual-hardness setups (e.g., 85A front/88A rear) for optimal pivot/stability balance

Pro tip: Test wheels in 5A increments—the difference between 80A and 85A can feel like skating on concrete versus carpet. Indoor rinks often mandate ≤78A wheels to protect flooring, demonstrating how context dictates hardness choice.

Wheel Diameter and Profile: Finding Your Perfect Fit

The diameter and profile of your inline skate wheels dramatically impact your skating experience, affecting everything from speed to maneuverability. While beginners often focus only on hardness, professional skaters know these dimensional factors can make or break performance.

How Wheel Diameter Affects Your Ride

Wheel sizes typically range from 54mm (aggressive skating) to 125mm (speed skating), with each size offering distinct advantages:

- Small wheels (54-68mm): Lower center of gravity enhances stability for tricks (e.g., Undercover Team Blank 58mm). Perfect for skate parks and technical street skating where quick pivots matter more than speed.

- Mid-range wheels (70-84mm): The versatile sweet spot for urban skating (like Hyper Concrete Plus 80mm). Balances acceleration with enough roll to maintain comfortable cruising speeds.

- Large wheels (90-125mm): Maximize speed with fewer rotations (ideal for marathon skaters). However, they require stronger ankle support and change the frame’s geometry significantly.

The Science of Wheel Profiles

Beyond diameter, the wheel’s profile (cross-sectional shape) determines how it interacts with surfaces:

- Round profile: The most common shape (like Labeda Asphalt) provides predictable grip and smooth transitions between edges – excellent for beginners learning proper technique.

- Bullet profile: Tapered edges reduce surface contact for less friction. Speed skaters use this to shave milliseconds off lap times, but it sacrifices stability in turns.

- Flat profile: Maximum surface contact creates superior grip for aggressive skaters doing slides and grinds, though it generates more rolling resistance.

Pro tip: Mix profiles in your setup – many urban skaters use slightly rounder wheels in front for control with flatter wheels in back for push efficiency. Always check your frame’s maximum wheel size tolerance before upgrading diameters, as exceeding it stresses the chassis and alters your center of balance dangerously.

Wheel Materials and Construction: The Hidden Performance Factors

Beyond hardness and size, the materials and manufacturing processes used in wheel construction significantly impact durability, rebound, and energy transfer. Understanding these technical aspects helps skaters make informed decisions when selecting premium wheels.

Urethane Formulations: More Than Just Hardness

Modern inline skate wheels use specialized urethane compounds with varying molecular structures:

| Material Type | Characteristics | Best For | Example |

|---|---|---|---|

| Standard Urethane | Balanced rebound (75-80%), moderate wear rate | Recreational skating, beginners | Rollerblade Hydrogen 80mm |

| High-Rebound Urethane | 85-92% energy return, faster wear | Competitive skating, speed | Matter G13 110mm |

| Hybrid Compounds | Reinforced with additives for abrasion resistance | Urban skating, rough surfaces | Hyper Concrete Plus |

Core Technologies Explained

The wheel’s internal core affects weight distribution and heat dissipation:

- Aluminum cores: Used in speed skating wheels (like MPC Black Magic) for maximum energy transfer but require careful temperature management

- Composite nylon cores: Common in urban wheels, offering vibration dampening (seen in Undercover wheels)

- Hubless designs: Some aggressive wheels eliminate cores entirely for better slide characteristics

Manufacturing Processes Matter

Premium wheels use injection molding for consistent density, while cheaper alternatives may use compression molding which can create air pockets. The curing process also affects performance:

- Slow-cured urethane: Develops superior molecular bonds (2-3 day process)

- Fast production: Leads to inconsistent hardness and rebound characteristics

Pro tip: Check wheel edges for molding lines – high-quality wheels have minimal flash and uniform coloring throughout. Store wheels away from UV light and ozone sources to prevent premature hardening of the urethane compound.

Wheel Rotation and Maintenance: Maximizing Performance and Longevity

Proper wheel care extends their lifespan by up to 40% and maintains optimal performance. Many skaters neglect this crucial aspect, leading to uneven wear, vibration, and reduced control. Understanding rotation patterns and maintenance techniques can transform your skating experience.

Advanced Rotation Strategies

The standard “front-to-back” rotation isn’t enough for serious skaters. Implement these professional techniques:

- X-pattern rotation: Move wheels diagonally (front left to rear right) to compensate for natural skating asymmetries

- Pressure-based rotation: Identify your dominant push foot and rotate those wheels more frequently (every 2-3 sessions for aggressive skaters)

- Dual-hardness rotation: When using mixed durometer setups (common in slalom), maintain hardness positions while rotating within zones

Wheel Maintenance Procedures

Follow this comprehensive maintenance routine every 10-15 skating hours:

- Cleaning: Use isopropyl alcohol (70%) and a soft brush to remove embedded debris from wheel grooves

- Inspection: Check for coning (uneven wear patterns) and measure diameter variance – replace if difference exceeds 3mm

- Edge maintenance: Lightly sand rounded edges with 120-grit sandpaper to restore grip (for non-speed wheels)

- Bearing care: Clean bearings simultaneously to prevent contaminants from damaging wheel cores

Troubleshooting Common Wheel Issues

Address these frequent problems with professional solutions:

| Problem | Cause | Solution |

|---|---|---|

| Vibration at speed | Uneven wear or flat spots | Rotate immediately and check frame alignment |

| Excessive sliding | Hardened urethane or contaminated surface | Clean with urethane conditioner or replace if >2 years old |

| Premature wear | Improper durometer for surface | Switch to harder wheels for smooth surfaces, softer for rough |

Pro tip: Keep a wheel log noting installation dates, rotations, and wear patterns. High-performance skaters should measure wheel diameters monthly with digital calipers – losing just 5mm can significantly affect your center of gravity and push efficiency.

Advanced Wheel Selection: Matching Wheels to Your Skating Discipline

Professional skaters know wheel selection requires understanding the nuanced demands of different skating disciplines. The optimal wheel setup varies dramatically between aggressive street skating and marathon racing, with each discipline requiring specific performance characteristics.

Discipline-Specific Wheel Requirements

Here’s how wheel needs differ across major skating styles:

| Discipline | Ideal Hardness | Optimal Diameter | Key Features | Top Performer |

|---|---|---|---|---|

| Aggressive Street | 88A-94A | 54-60mm | Flat profile, slide-friendly | Undercover Team Blank |

| Urban/Fitness | 83A-88A | 76-84mm | Shock absorption, durability | Hyper Concrete Plus |

| Speed Skating | 86A-90A | 100-125mm | Bullet profile, high-rebound | Matter G13 |

| Artistic/Slalom | 80A-85A | 72-80mm | Dual-hardness setups | Rollerblade Supreme |

Special Considerations for Competitive Skaters

Elite athletes must account for additional factors:

- Temperature effects: Urethane hardens in cold (add 5A to summer durometer for winter skating)

- Wheel break-in periods: New wheels need 3-5 sessions to reach optimal grip (especially important for downhill skaters)

- Competition surfaces: World Skate regulations specify different wheel requirements for banked track vs. flat track racing

Emerging Technologies and Future Trends

The wheel industry is evolving with these innovations:

- Smart urethane compounds: Temperature-adaptive materials that adjust hardness based on conditions

- Sustainable alternatives: Bio-based urethanes with comparable performance to petroleum-based versions

- Modular wheel systems: Interchangeable outer sleeves for quick hardness changes

Pro tip: For mixed-discipline skaters, maintain separate wheel sets rather than compromising. The cost of specialized wheels pays off in performance and safety. Always check governing body regulations before competition – some events mandate specific wheel certifications or maximum diameters.

Custom Wheel Setups: Advanced Configuration Techniques

Mastering wheel configurations can unlock 20-30% performance gains for experienced skaters. Unlike standard setups, custom configurations account for individual skating style, weight distribution, and specific terrain challenges.

Asymmetric Wheel Arrangements

Professional skaters often use non-uniform setups to compensate for biomechanical differences:

- Staggered diameters: Larger wheels (2-4mm) in the rear for speed maintenance with smaller fronts for maneuverability

- Differential hardness: Softer front wheels (e.g., 85A) for grip with harder rears (88A) for push efficiency

- Mixed profiles: Round profile front wheels for control with bullet profile rears for reduced friction

Frame-Specific Optimization

Different frame types require unique wheel considerations:

- Rockered frames: Use identical wheel hardness throughout to maintain the natural rocker effect

- Flat frames: Can benefit from slight size variations (1-2mm) to create a “natural rocker” through wear

- Trinity mount systems: Allow larger wheels but require careful durometer matching to prevent frame stress

Performance Tuning Process

Follow this professional tuning methodology:

| Step | Process | Measurement Tool |

|---|---|---|

| 1. Baseline Analysis | Video analysis of stride mechanics | High-speed camera |

| 2. Pressure Mapping | Identify contact points and weight distribution | Pressure-sensitive footbeds |

| 3. Prototype Testing | Test 3-4 configurations in controlled conditions | GPS speed tracker, heart rate monitor |

Pro tip: For downhill skaters, create a “progressive” setup with gradually increasing hardness from front to back (e.g., 85A-86A-87A-88A). This provides maximum front grip while allowing controlled slides in the rear. Always mark wheel positions with colored dots during testing to track performance variations accurately.

Performance Optimization and Long-Term Wheel Management

Maximizing wheel performance requires a systematic approach that combines immediate tuning with ongoing maintenance strategies. This final section synthesizes all previous concepts into a comprehensive management system for serious skaters.

Comprehensive Performance Optimization Matrix

Use this decision framework to fine-tune your wheel setup:

| Performance Goal | Hardness Adjustment | Diameter Strategy | Rotation Frequency | Expected Lifecycle |

|---|---|---|---|---|

| Maximum Speed | +5A over standard | Largest frame-compatible | Every 8-10 hours | 150-200 miles |

| Urban Durability | -3A from standard | Mid-range (76-80mm) | Every 5-7 hours | 250-300 miles |

| Technical Control | Mixed (85A/88A) | Staggered diameters | Every 3-5 hours | 100-150 miles |

Advanced Lifecycle Management

Implement these professional-grade maintenance protocols:

- Phase-based rotation: Different rotation patterns during break-in (first 20%), peak performance (middle 60%), and end-of-life phases

- Wheel pairing: Match wheels by measured diameter (within 0.5mm) rather than age for competition setups

- Environmental conditioning: Store wheels at 15-25°C with 40-60% humidity to prevent premature hardening

Quality Assurance Framework

Establish these validation checkpoints for competition-ready wheels:

- Rebound testing: Drop test from 1m height should yield ≥80% rebound for speed wheels

- Hardness verification: Use a digital durometer to check for consistency (±1A tolerance)

- Visual inspection: Examine under UV light for stress cracks in the urethane matrix

- Rolling resistance test: Measure coasting distance on standardized surface

Pro tip: Maintain a “wheel passport” documenting each set’s mileage, rotation history, and performance characteristics. High-level competitors should retire wheels after 70% of their expected lifecycle to ensure consistent performance during critical events. Always cross-reference your setup with weather reports – humidity above 70% may require switching to softer wheels for adequate grip.

Conclusion: Rolling Forward With Confidence

Selecting the perfect inline skate wheels requires balancing multiple factors – from durometer hardness and wheel diameter to specialized profiles and advanced materials. We’ve explored how different skating disciplines demand unique setups, how proper rotation extends wheel life, and how custom configurations can unlock your full potential. Remember that the best wheels are those that match your specific skating style, weight, and terrain. Whether you’re an aggressive street skater needing durable 58mm wheels or a speed skater optimizing 110mm high-rebound setups, this knowledge empowers you to make informed choices. Now it’s time to put theory into practice – assess your current wheels, experiment with different configurations, and experience the transformation in your skating performance.

Frequently Asked Questions About Inline Skate Wheels

What’s the difference between indoor and outdoor skate wheels?

Indoor wheels (74A-78A) are softer to grip polished rink surfaces and protect flooring, while outdoor wheels (80A-88A) are harder to resist pavement abrasion. Outdoor wheels often feature reinforced urethane compounds and slightly larger diameters (76mm+) to handle cracks and debris. For mixed use, 82A-85A hybrids like the Rollerblade Supreme offer balanced performance.

How often should I rotate my skate wheels?

Rotate wheels every 8-10 skating hours for recreational use, or every 3-5 hours for aggressive skaters. Use an X-pattern rotation (front left to rear right) to compensate for natural wear patterns. Measure diameters monthly – replace wheels when the difference exceeds 3mm or when flat spots develop that affect rolling smoothness.

Why do my wheels wear out unevenly?

Uneven wear typically comes from: 1) Dominant pushing side wearing faster, 2) Improper frame alignment, 3) Incorrect durometer for your weight (heavier skaters need harder wheels), or 4) Excessive braking on one side. Try a staggered rotation pattern and consider mixing hardness (softer on dominant side) if the problem persists.

Can I mix different wheel brands on my skates?

While possible, mixing brands risks inconsistent performance due to varying urethane formulas. If necessary, keep the same durometer and diameter, and place similar rebound wheels together (front or back pairs). For optimal results, use matched sets – wheels like the Hyper Concrete Plus are engineered for uniform performance across all positions.

How does temperature affect wheel performance?

Cold weather (below 10°C/50°F) hardens urethane by 5-10A, reducing grip. In winter, use wheels 5A softer than normal. Hot pavement (above 30°C/86°F) softens wheels, increasing grip but accelerating wear. Store wheels at room temperature and allow 15 minutes to acclimate before skating in extreme conditions.

What wheel setup is best for heavy skaters?

Skaters over 200lbs should: 1) Choose wheels 5-10A harder than standard recommendations, 2) Opt for reinforced cores (like aluminum hubs in MPC wheels), 3) Use mid-range diameters (80-90mm) for stability, and 4) Rotate more frequently (every 5-7 hours). The Labeda Asphalt 85A in 80mm is an excellent durable choice.

How can I make my wheels last longer?

Extend wheel life by: 1) Avoiding asphalt over 35°C, 2) Cleaning debris after each session, 3) Using proper rotation patterns, 4) Storing away from UV light, and 5) Matching durometer to surface (softer for rough terrain). High-quality wheels like Undercover Blanks can last 2-3x longer than budget options when properly maintained.

Are expensive wheels worth the investment?

Premium wheels offer: 1) More consistent urethane formulas (better rebound), 2) Precision molding (fewer defects), 3) Advanced cores (better energy transfer), and 4) Longer wear life. For casual skating, mid-range wheels (€50-80/set) suffice, but competitive skaters should invest in high-end options like Matter G13 for measurable performance gains.